The Power Tool for Laser Engraving Photographs!

PhotoGraV has been designed specifically for Laser Engravers.

Buy PhotoGrav 3.1

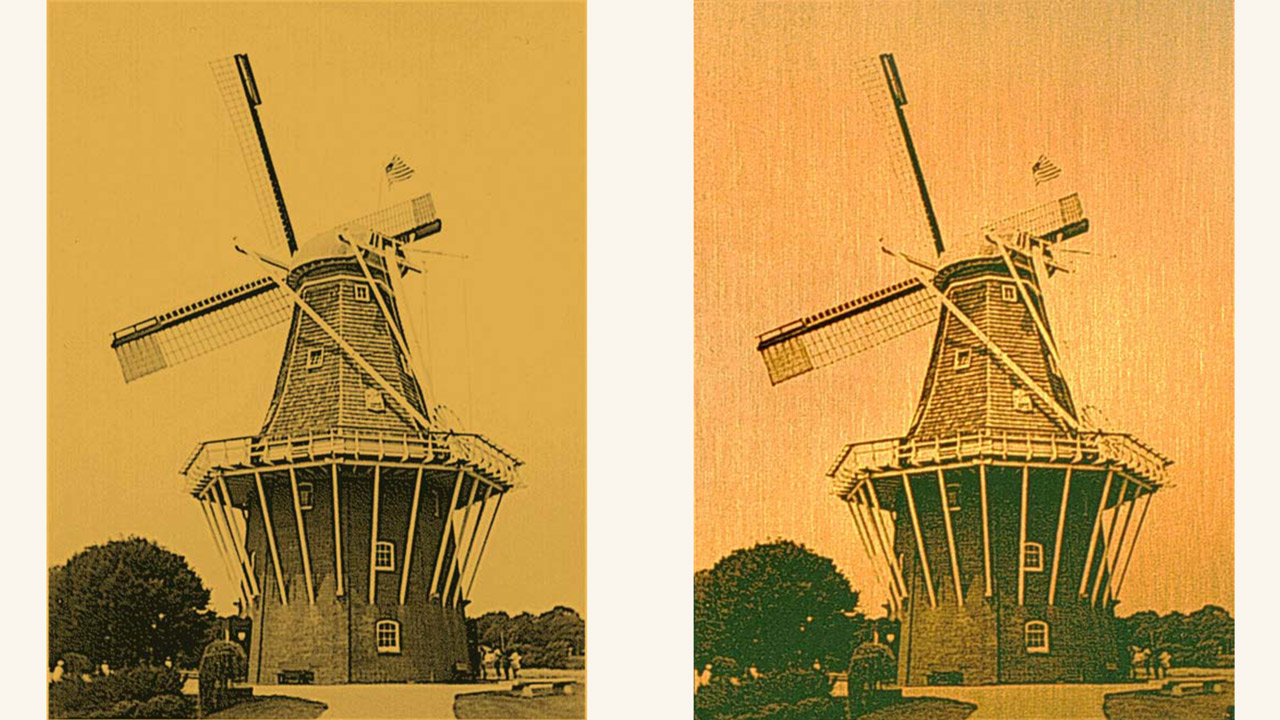

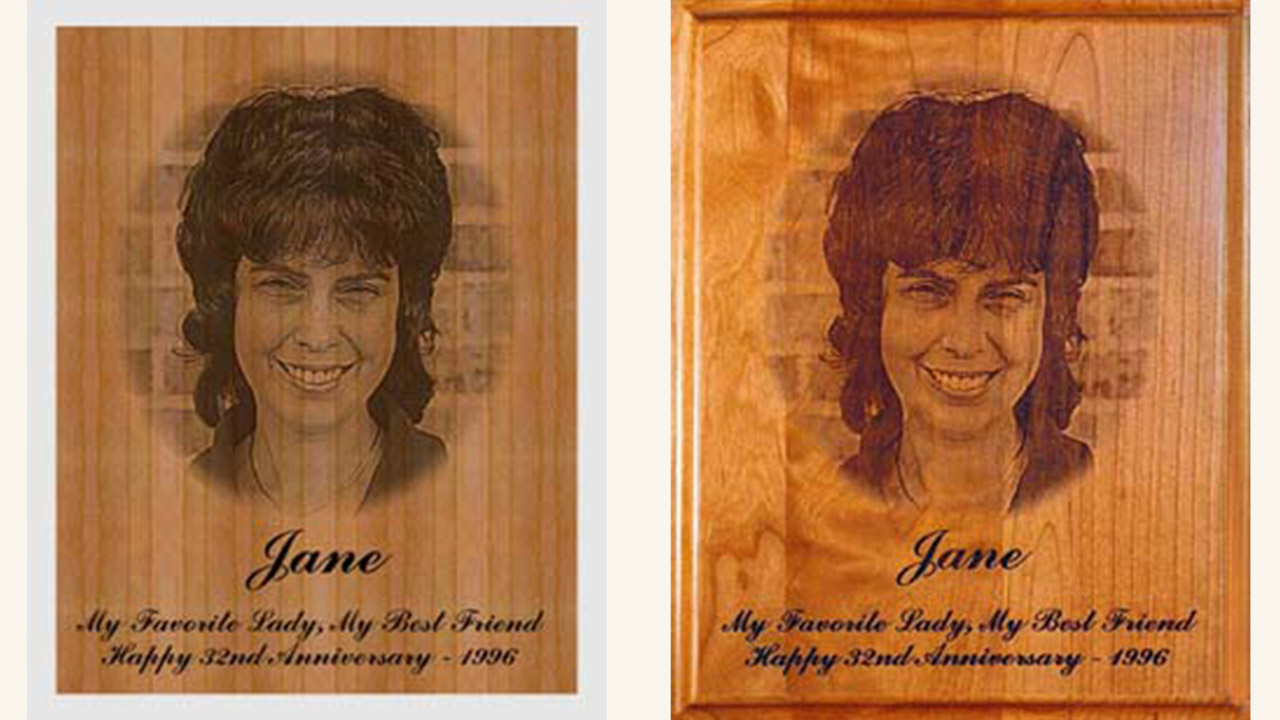

The objective of the program is to efficiently process digital photographs so that they can be engraved on a variety of common materials with confidence that the engraved photographs will be of superb quality.

Traditionally, the engraving of photographs has been difficult and has been a hit or miss endeavor resulting in many discarded products. The process has been so difficult and time consuming, in fact, that many engraving shops simply do not offer engraved photographs as one of their products.

Easy To Use

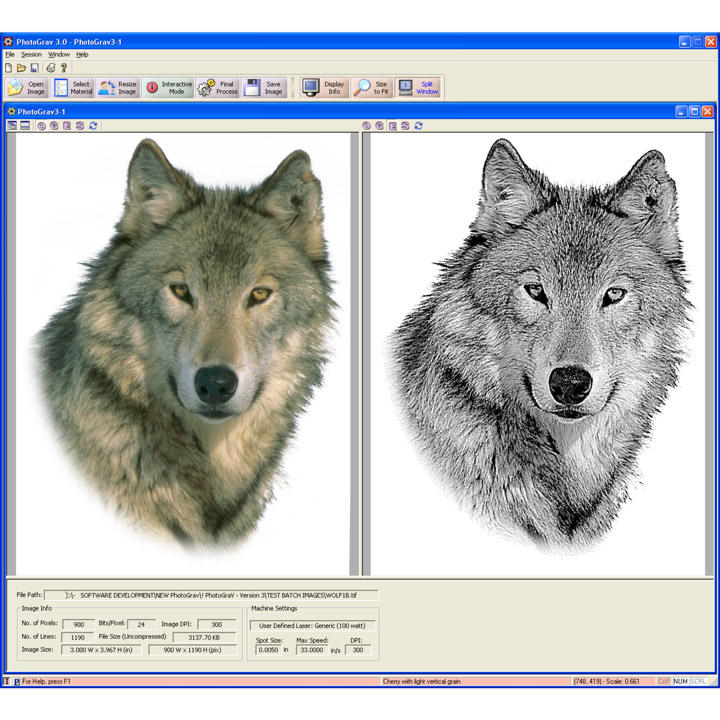

Step 1

Scan image as windows bitmap

Step 2

Open the image in PhotoGraV

Step 3

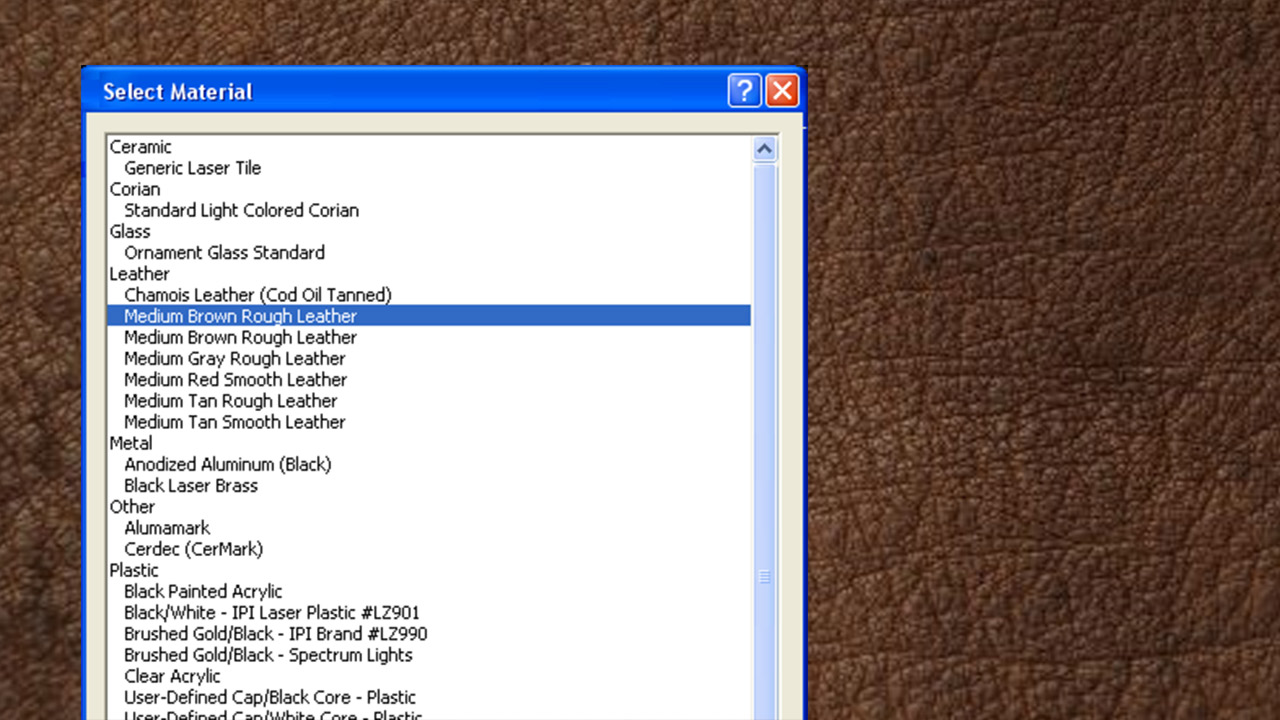

Choose the material type you will be engraving

Step 4

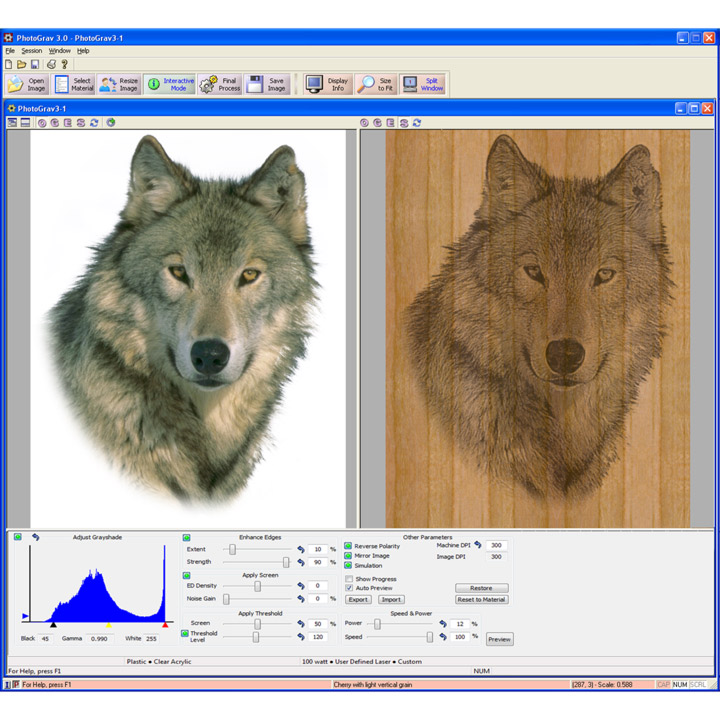

Select the Final Process button.

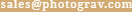

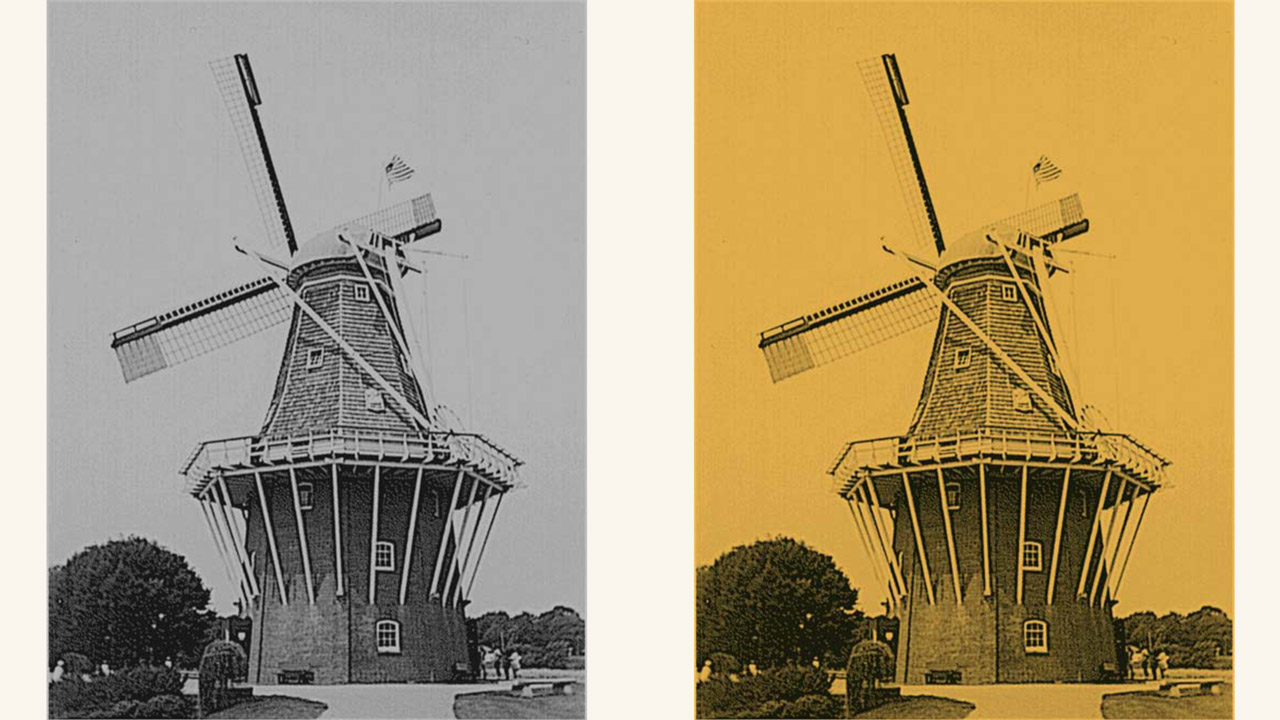

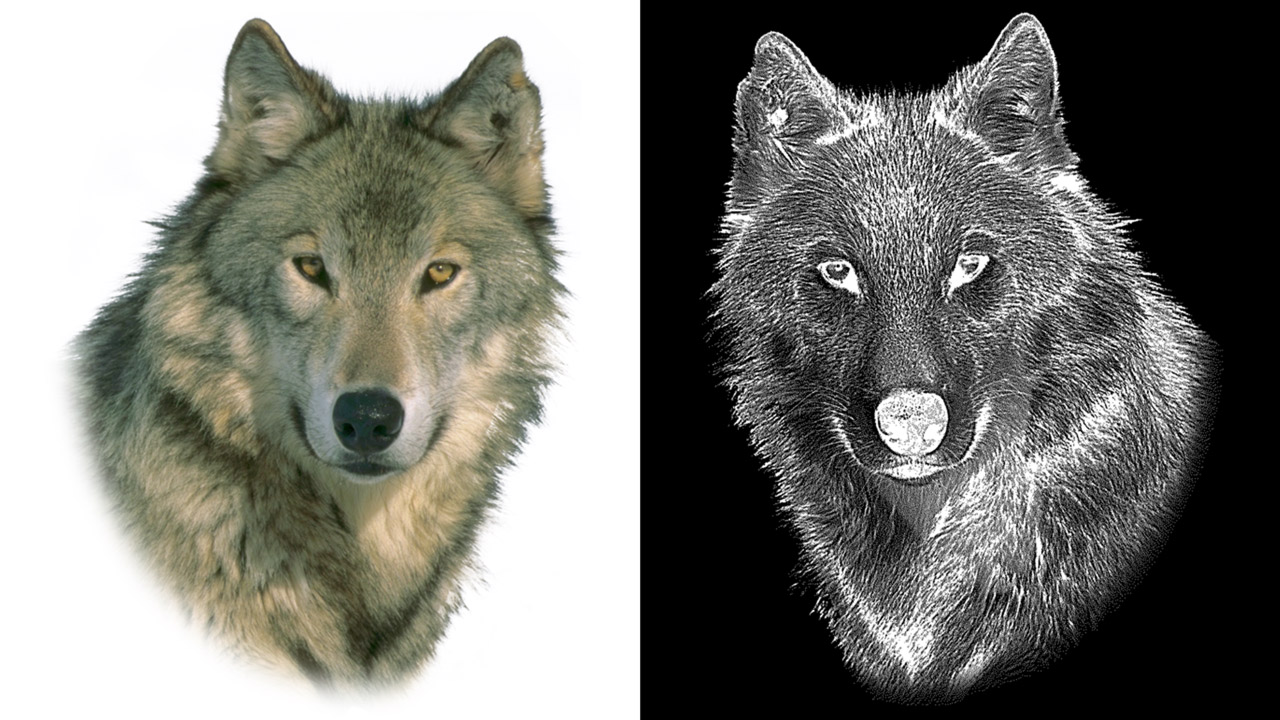

The next thing you see on your computer monitor is a simulation of what the image will look like when it is actually engraved on the material you have chosen.

Now reduce the time & effort when engraving photographs!

Features

Automated

Automated application of these tools to the subject photo.

Simulation

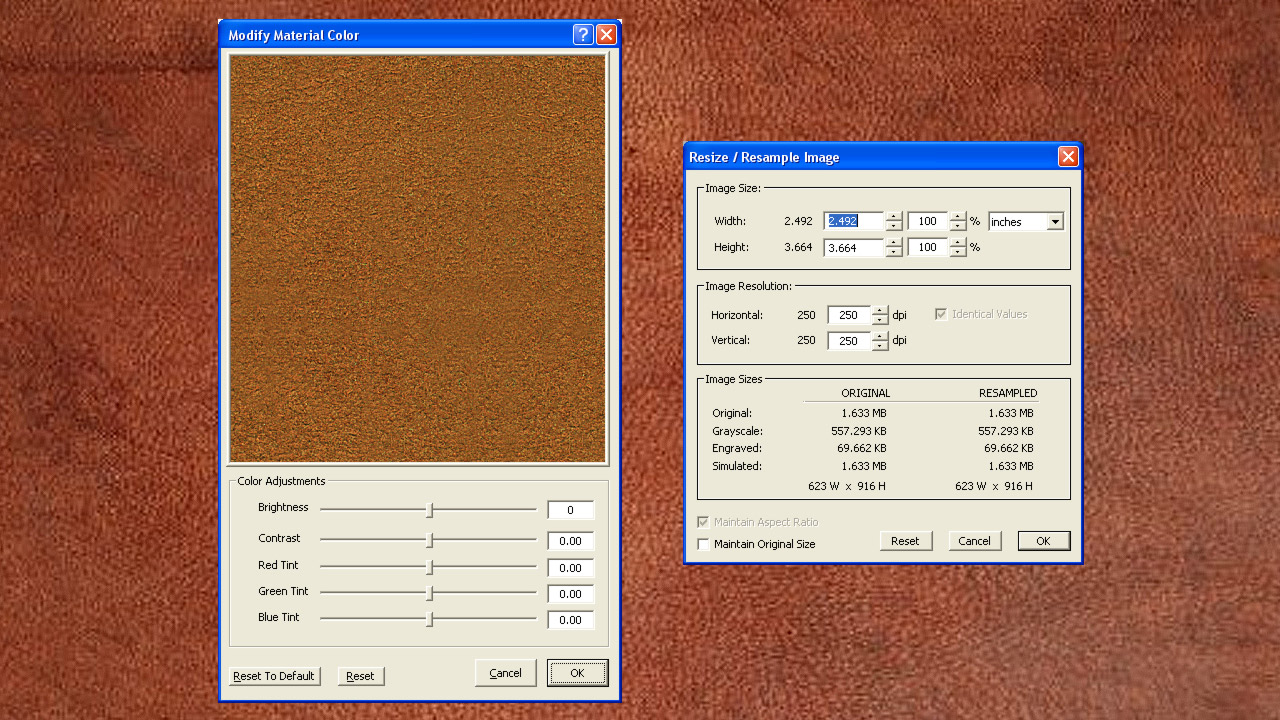

Simulation of the engraving process for common materials so the

“engraved product” can be inspected before it is actually engraved.

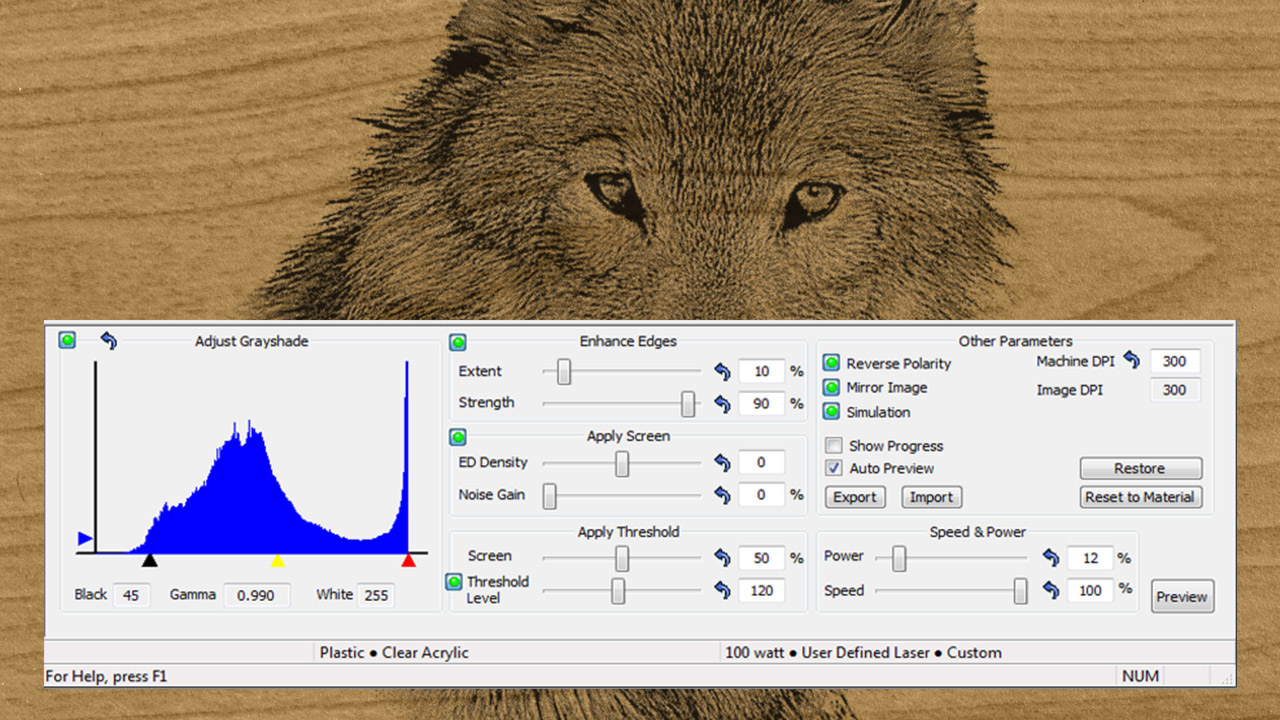

Interactive

Interactive process with adjustable enhancements and real-time visual feedback.

Reports

Reports and color proofs for customer approval and reference.

User Defined

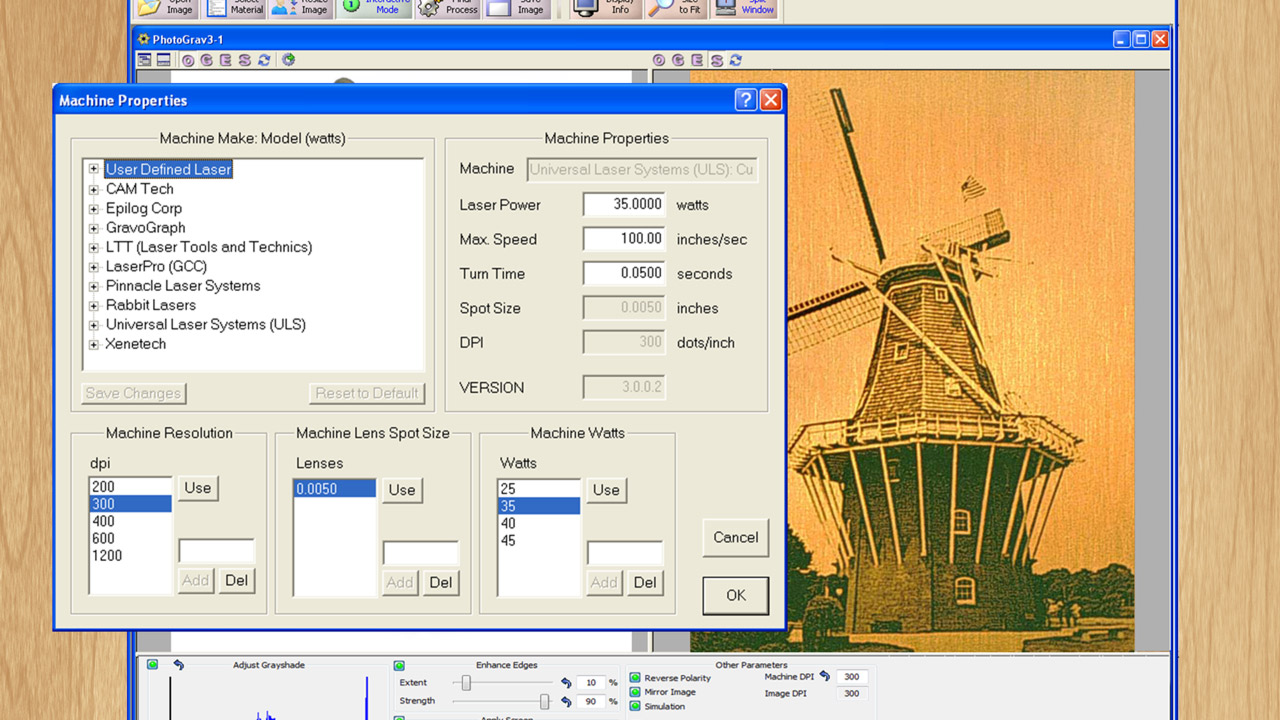

User defined parameter sets can be saved for further customization.

Calibrated

Calibrated to most laser engraving equipment and common materials.

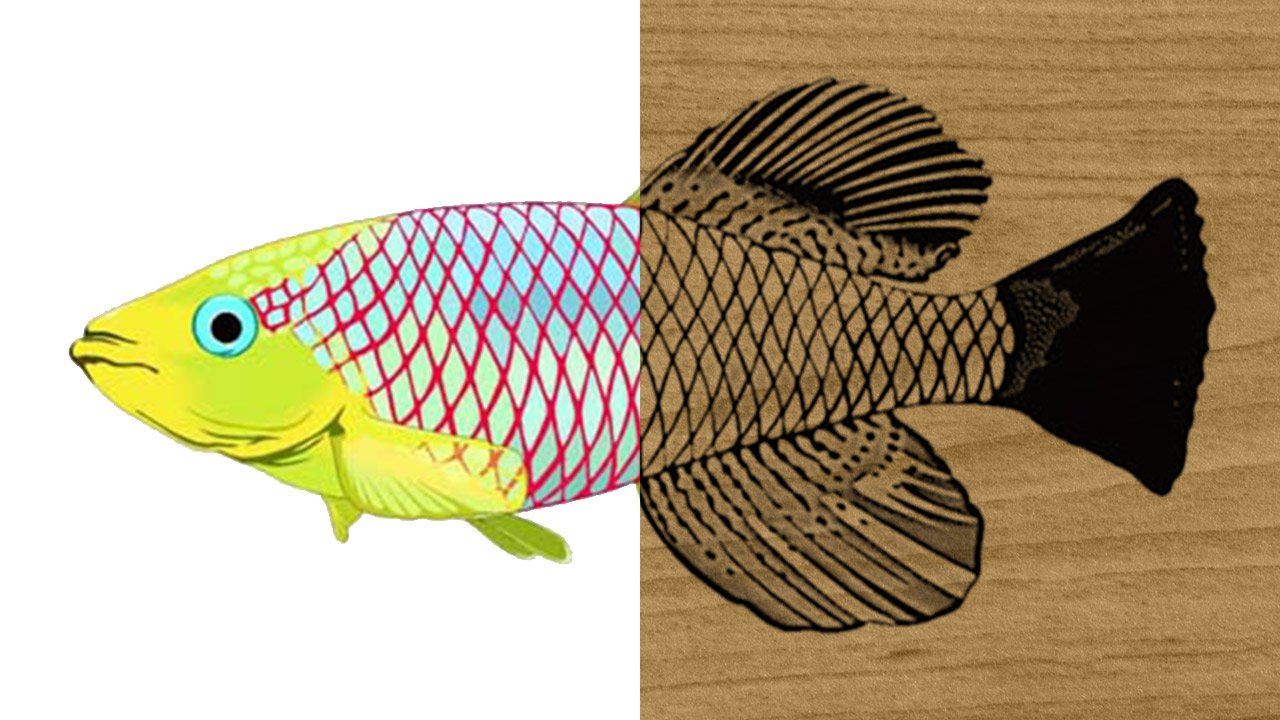

Color Clipart

Color Clipart from CorelDraw can be easily engraved by processing with PhotoGraV.

Simulations

PhotoGraV simulates more than 20 engraving materials including: cherry and walnut wood; clear and black-painted acrylic; black laser brass and anodized aluminum; a variety of generic leather materials; and many plastics with either a white or black core and with a variety of caps including brushed gold and most solid colors.

PhotoGraV's processing functions have been tuned and optimized for each of these materials and the appropriate optimized parameters are automatically loaded whenever a new material is selected.

Note: Actual results may vary from simulation.

Negative image produced in saved file.

PhotoGraV automatically compensates for the engraving peculiarities of each material in the process of creating the "engraver-ready" processed image. For example, photos to be engraved on clear acrylic are automatically mirror-imaged and produced at a "negative" polarity. Of course, you can override these automatic features at any time to produce special effects if so desired.